What is Continuous Insulation (CI) and Why Do I Need It?

Continuous insulation is a type of home insulation that involves installing a continuous layer of insulation over the entire exterior surface of a building, including the walls, roof, and foundation. The goal of continuous insulation is to eliminate thermal bridging, which is the transfer of heat through materials with a higher thermal conductivity, such as wood studs or steel framing members.

Air Leakage is a Significant Source of Heat Loss

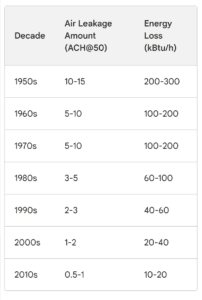

The role of continuous insulation in reducing air leakage is significant. By installing a continuous layer of insulation over the entire exterior surface of a building, including walls, roof, and foundation, it creates an airtight seal that significantly reduces the amount of air infiltration into the building. Here is a table of typical air leakage and consequent energy loss for typical home construction by decade:

Air leakage occurs when air moves through gaps and cracks in the building envelope, such as around windows, doors, and other penetrations. This can lead to a loss of conditioned air, higher energy bills, and reduced indoor comfort. By eliminating gaps and cracks, continuous insulation helps to reduce air leakage and improve energy efficiency.

Continuous insulation reduces air leakage in several ways. Continuous insulation creates an airtight seal around the building envelope, which significantly reduces the amount of air infiltration. It also helps to minimize thermal bridging. Thermal bridging occurs when heat moves through materials with a higher thermal conductivity, such as wood studs or steel framing members, leading to hot or cold spots on interior surfaces.

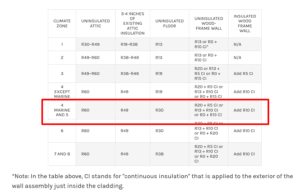

The energy.gov recommendations for adding insulation to homes with existing wall insulation, the typical situation in cold climates like New England that lie within climate zones 5 or 6, is to add a layer of CI (continuous insulation) with an R value of 10. That usually means adding an insulation system of insulation panels along with specialized sealants, tapes and fasteners between the exterior cladding and the framing. Here is the energy.gov table:

Foam Board Panels are the Most Common CI Insulation Materials

The full system of continuous insulation typically includes the following components:

- Insulation Panels: The insulation panels used for continuous insulation are typically made of foam board materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate (PIR). These panels come in a variety of thicknesses and densities to provide the desired R-value (thermal resistance) for the specific climate zone where the building is located.

- Tapes: Specialized tapes are used to seal the joints between insulation panels to prevent air infiltration. These tapes are typically made of polyethylene or other durable materials that can withstand exposure to weather and UV radiation.

- Fasteners: Specialized fasteners are used to secure the insulation panels to the exterior surface of the building. These fasteners are typically made of plastic or metal and are designed to provide a secure attachment while minimizing thermal bridging.

- Sealants: Sealants are used to seal around windows, doors, and other penetrations in the building envelope to prevent air infiltration. These sealants are typically made of silicone, polyurethane, or other durable materials that can withstand exposure to weather and UV radiation.

The installation process for continuous insulation typically involves attaching the insulation panels to the exterior surface of the building using the specialized fasteners. The joints between the panels are then sealed using the specialized tapes, and any penetrations in the building envelope are sealed using the specialized sealants.

Continuous Insulation Increases R-Value and Decreases Air Leakage

Insulation R-value is a measure of how well insulation resists heat transfer. It indicates the ability of the insulation to reduce the amount of heat that flows through it. The higher the R-value, the more effective the insulation is at reducing heat loss. Insulation R-value is the primary factor in minimizing conductive heat transfer through the building envelope.

Reduced air leakage, on the other hand, is a measure of how well the building envelope prevents the flow of air through gaps, cracks, and openings. By reducing air infiltration, the amount of heat loss due to convective heat transfer is minimized. Convective heat transfer occurs when warm air escapes through gaps in the building envelope and is replaced by cooler outside air. This can cause drafts and temperature fluctuations, which can reduce comfort and increase energy consumption.

Both insulation R-value and reduced air leakage play important roles in minimizing heat loss in buildings. While insulation R-value primarily affects conductive heat transfer through the building envelope, reduced air leakage primarily affects convective heat transfer. A combination of high insulation R-value and reduced air leakage is necessary to achieve optimal energy efficiency and reduce heat loss in buildings.

At Green Insulation Group our mantra is reduce, reuse, recycle. One of our specialties is the distribution of XPS, EPS and polyiso panel insulation that can be reused. Save money, lower your heating bills, and keep insulation out of landfills.